Spot Colors and Digital Printing Design Tips and Best Practices, Part I

Recently, we delved into the basics of spot colors. If you’re curious how they differ from process colors or when they should be used – we recommend you pause here and check out our introductory article.

Start With the End in Mind

Have an idea of what printing process you’ll be using – that way you can design accordingly. Determining this involves many factors, including:

• How many colors are used in the design?

• How critical is color within the job?

• Can CMYK or Extended Gamut replicate the colors accurately? (More on this in a moment)

• What is your budget?

To understand the rationale behind these factors, be sure to check out our last post. If process printing is the route you’ve chosen to take, you’ll need to determine if you can hit your colors within a margin you’re satisfied with (otherwise, design modification may be needed). For that, you’ll need some help.

Pantone Color Bridge: A Designer’s Best Friend.

If you know the colors you’re trying to achieve (corporate colors or brand logos, for example), it’s relatively easy to see how close you can get using the four-color printing process.

While there are a few ways to accomplish this, the most reliable method is turning to a Pantone Color Bridge. This guide lets you see how the colors will look once printed rather than relying on simulations generated by your computer monitor.

Inside, you’ll see side-by-side comparisons of actual Pantone swatches with replicated four-color builds. (Full disclaimer: it’s not always pretty.) Remember, CMYK can only reproduce roughly 55% of the Pantone library. Some builds will look great and you’ll happily live with tradeoff of consistency for the flexibility process printing offers. In other cases, the builds just won’t cut it.

*Note: Inside your Pantone Color Bridge, each swatch will show the CMYK (or CMYKOGV) values needed to achieve that color. We’ll refer back to this next week.

Looking Beyond CMYK

If CMYK cannot accurately reproduce your spot colors, fear not! Your colors could benefit from seven-color process printing, known as Extended Gamut, which can match roughly 90% of Pantone spot colors.

You’ll want to refer to a special Extended Gamut guide, which will display how printing systems using this technology can replicate color when printing with CMYK plus Orange, Green and Violet. Typically, these swatches will showcase the solid (Pantone) color compared to both the process (CMYK) and Extended Gamut (notated as ‘XG’) colors.

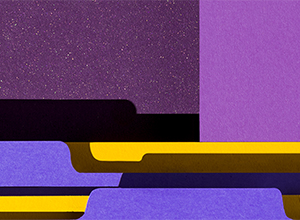

Coated Versus Uncoated Spot Colors Swatches

Another helpful bit of information the Pantone guides share is how your spot or composite process colors will look when printed on coated or uncoated paper. This is depicted either by a ‘C’ or ‘U’ marked on the swatch. You’ll likely see other abbreviations: ‘C’ (coated spot), ‘CP’ (coated process), ‘XGC’ (extended gamut coated), ‘U’ (uncoated spot) and ‘UP’ (uncoated process).

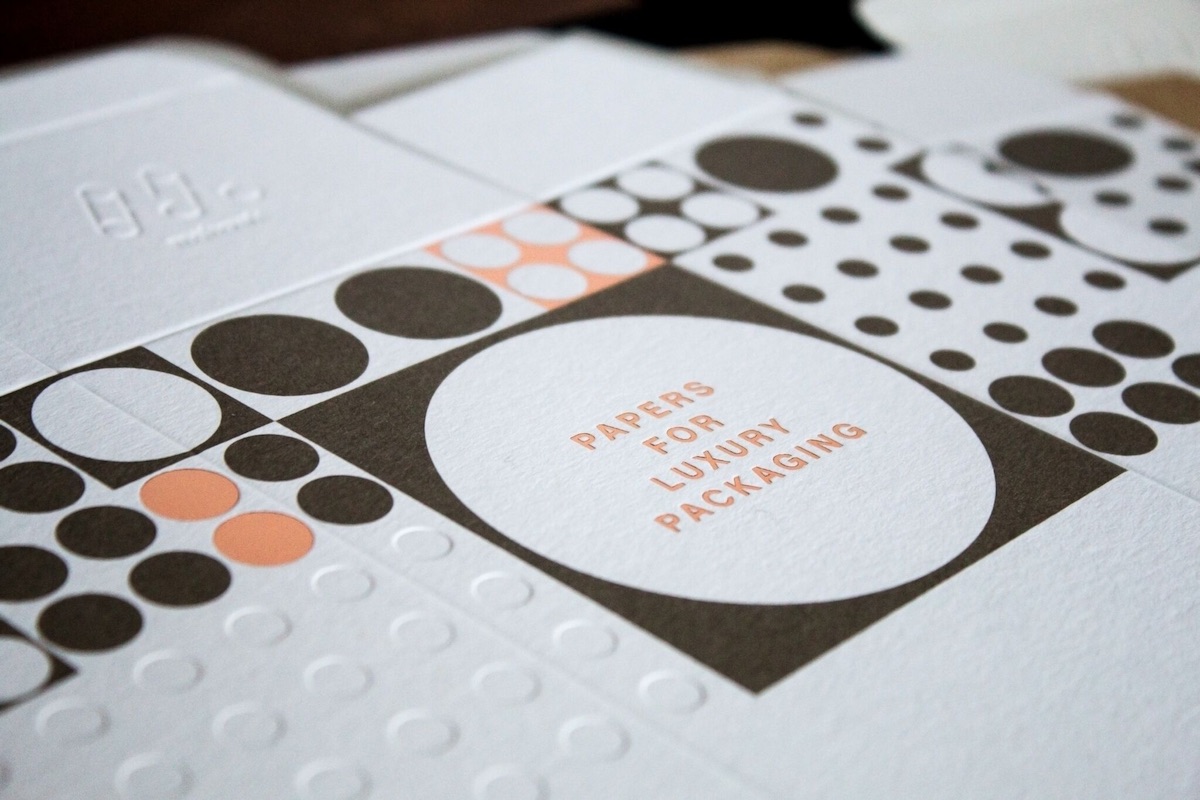

Immediately, you’ll notice a difference in how a swatch appears between the two paper types. Colors printed on uncoated papers tend to be darker as ink is absorbed into the substrate and sits beneath its surface. Meanwhile, colors printed on coated stocks tend to be brighter and more vibrant as the finish allows the inks to sit atop the surface of the paper.

You will also see that uncoated swatches not only appear lighter than their coated counterparts within a Pantone Guide, but they also have lower CMYK values. This is done purposefully to offset the natural darkening that will occur when printing on uncoated substrates. When trying to replicate a spot color using a process build, you will want to use the CMYK value for the paper finish it is destined for.

Tricks to Finding a Good CMYK Match

If you have some say in the colors used in your design and you’ll be leaning on process printing, it is wise to choose colors that can be reproduced easily.

If you don’t own a Pantone Color Bridge and only have access to the Pantone Formula Guide it can be difficult to know how accurately a spot color can be reproduced using process printing.

However, there is a trick. You’ll notice that Pantone indicates the colors they feel can successfully be reproduced as process builds by placing four small dots beneath the Pantone number.

I Don’t Own a Pantone Guide. Now What?

While Pantone guides are a worthwhile investment for printers and designers alike, the truth is they can be very expensive. Fortunately, Pantone offers a free online tool that allows you to enter a Pantone name or number to obtain the CMYK (or CMYKOGV, for seven-color process printing) values.

And while it can be quite difficult to determine from your monitor if a spot color can adequately be reproduced using process colors, there is a workaround. Generally speaking, colors that have at least one CMYK ink value at or near 100% are more likely to provide a vibrant, consistent color than swatches with process color values all at low or mid values.

Alternatively, many digital front ends (or RIPs) of digital production presses have software tools that enable the operator to print out variations of a spot color to help achieve the desired reproduction. This takes into account the combination of a specific paper and the device’s toner/ink gamut in a current state.

Engage Your Local Printing Representative Early and Often

This article is intended to help answer questions you may have when designing for spot colors used in digital or traditional printing technologies. However, it’s always best to speak with your local printer. They can make recommendations and should have access to Pantone guides. Similarly, they may have gamut extension capabilities (ie. with an HP Indigo, Kodak NexPress or Xerox iGen 5) or metallic ink offerings to expand the range of spot colors you can achieve.

What's Next?

Next week we’ll discuss tips for designing and preparing your files and colors to best reproduce using CMYK processes.

Suggested Articles

Last week, we began our discussion on how to design for spot colors used in digital print technologies. This included how to determine which spot colors may reproduce accurately as CMYK builds and what information you can gather from the various Pantone guides.

In a previous post we dived deep into the nuances of color, including the differences between RGB and CMYK color spaces, when to use each and how to design for them. What about spot colors?

As digital printing evolves from compromise to sophisticated tool—advances in color, texture, and fiber papers push the boundaries of what's possible.