Understanding Spot Colors (and their Role in Digital Printing)

In a previous post we dived deep into the nuances of color, including the differences between RGB and CMYK color spaces, when to use each and how to design for them. What about spot colors?

What are Spot Colors?

To understand what spot colors are, you must first understand what they are not.

CMYK (also known as process or four-color) printing involves tiny halftone dots of color (Cyan, Magenta, Yellow and Black) being laid onto a substrate in combinations and formations that fools the human eye into perceiving continuous color.

Spot (sometimes referred to as solid) colors differ in that there is no mixing of colors in the printing process. Instead, colors come as pre-mixed recipes. As an example, a specific shade of green may be achieved through process printing by mixing certain combinations of yellow and cyan inks. However, differences in printers, inks and calibration settings could lead to very different results. Meanwhile, that same shade of green can be achieved with spot colors through a precisely pre-mixed recipe.

With spot printing, the result is a uniform and consistent color – always the same, from job to job and printer to printer.

Spot Colors versus CMYK

What are the pros and cons of both process and spot colors, and when should one be used over the other? Let’s discuss.

Use CMYK:

1. Whenever your printed piece involves full-color imagery or photography.

2. If jobs are not color critical, involve more than three colors, and keeping costs down is a priority. In spot color printing, because colors are not mixed, each Pantone®-designated color requires its own printing tower or color station. For jobs with many colors, spot colors can become very expensive.

3. When colors can accurately be reproduced using the four-color CMYK printing process (we discuss this in more detail in an upcoming post). According to Pantone®, about 55% of Pantone® spot colors can be matched using basic process printing, although that percentage grows significantly when an Extended Gamut process is used (more on that in a moment).

Use spot colors:

1. When your job is very color critical, such as brand-standard colors used on a logo.

2. If your job involves fewer than four colors, it can often be more affordable to have it printed using spot colors.

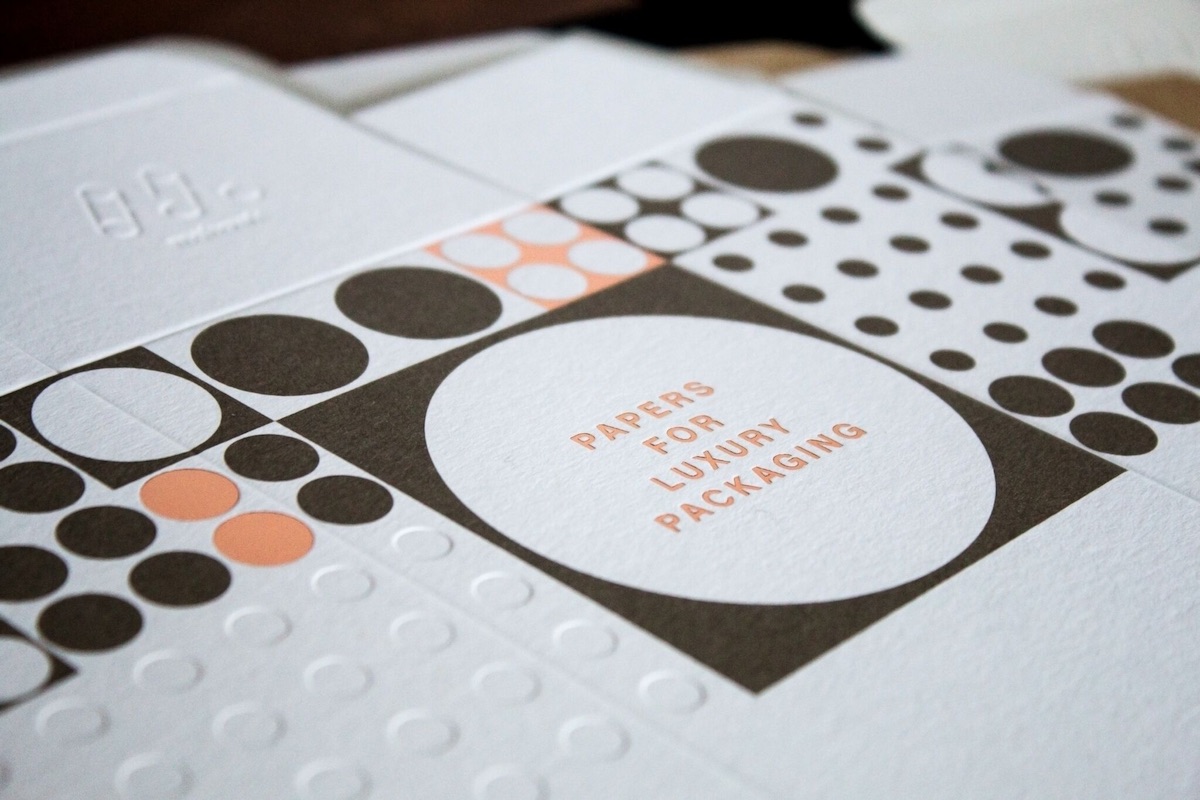

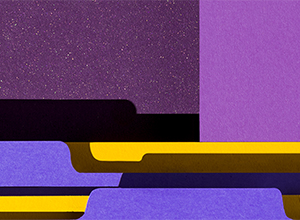

3. When using metallic or fluorescent colors, which can very difficult for the CMYK process to replicate.

4. If your design entails large area coverage of solids that must match from one piece to the next. There are ways to achieve this through process printing (such as adding noise or texture), but using spot colors will ensure greater consistency.

5. If a printed piece requires very small font, reverse type, or fine lines of 0.5-point or less (especially curved). It is difficult for halftone dots to confine to very fine details, resulting in jagged effects.

Achieving Spot Colors with Digital Printing

The thought of each spot color commanding its own individual printing tower and color station probably has you thinking this printing process is reserved solely for offset printing. While this is mostly true, there are a growing number of digital print technologies that can accurately reproduce spot colors through Extended Gamut solutions.

What is Extended Gamut?

Extended Gamut is a method used in digital printing that extends the press’ color gamut and allows it to more accurately hit a wider range of colors. This is made possible by introducing additional base inks (typically Orange, Green and Violet) into the printing process. According to Pantone®, a seven-color process (CMYKOGV) can match roughly 90% of Pantone® spot colors.

In the past, a digital printer needing to recreate an orange would be forced to combine yellow and magenta inks (typically with very poor results). Now with Extended Gamut, orange ink can simply be used, resulting in cleaner and more accurate representations.

What are the Benefits of Extended Gamut?

With Extended Gamut, the worlds of spot color and digital printing collide, bringing together the ability to achieve vibrant, accurate colors in short-runs and with variable data.

For brands and designers, Extended Gamut makes digital printing and its benefits more accessible than ever before. For printers, this technology represents another tool in the toolbox – widening current offerings and enabling new business opportunities.

What Digital Print Technologies Offer Extended Gamut Compatibility?

We’ll exclude wide format inkjet technology from the scope of this discussion for now, so below are some examples using sheet-fed dry toner or liquid toner digital technology:

Hewlett-Packard

Select models of HP Indigo digital presses offer up to 7 on-press ink stations. Operators can choose between Gamut Extension colors (Orange, Green or Violet) or special effect inks (White, Transparent, Light Cyan, Light Magenta, Light Black, and UV Red).

For jobs that require a specific Pantone® spot color, an on-site mixing system (HP IndiChrome off-press) allows users to specify and create a specific spot color using a combination of 11 base colors.

Xerox Corporation

The Xerox iGen 5 Press takes an alternate route to achieving Extended Gamut through an optional fifth-color housing used for Orange, Green or Blue dry inks. These colors were chosen to help match a greater number of Fortune-500 corporate colors whose requirements fall within this color gamut.

Additionally, the Xerox Color 800i and 1000i Presses make use of an optional fifth color housing for metallic gold, silver and clear specialty dry inks.

Kodak

Select Kodak Nexpress models can be equipped with a Fifth Imaging Unit to offer additional colors, glossing, and even MICR to add those finishing touches to client jobs.

What's Next?

Check back in the coming weeks as we share tips on designing for and implementing spot colors using digital print processes.

Production Notes

Suggested Articles

Recently, we delved into the basics of spot colors. If you’re curious how they differ from process colors or when they should be used – we recommend you pause here and check out our introductory article.

Last week, we began our discussion on how to design for spot colors used in digital print technologies. This included how to determine which spot colors may reproduce accurately as CMYK builds and what information you can gather from the various Pantone guides.

As digital printing evolves from compromise to sophisticated tool—advances in color, texture, and fiber papers push the boundaries of what's possible.